Video Transcript

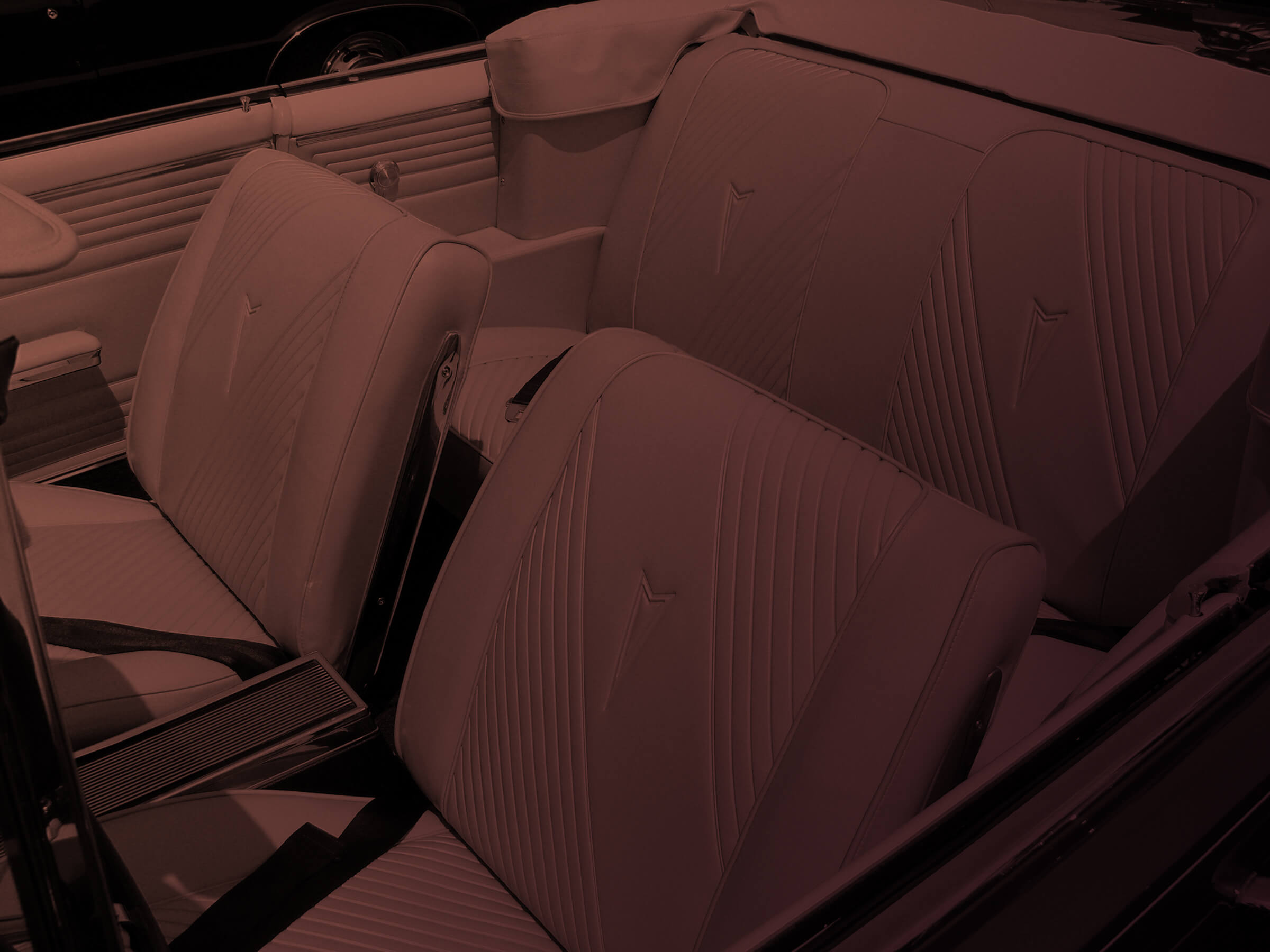

Hi, I’m Ron Halbritter, technical advisor for Legendary Auto Interiors and I’d like to welcome you to the Legendary Studio, where today we’re going to show you the proper way to install a bucket front seat upholstery kit for our 1969 Charger, which is going to include new seat covers, new padding, and our installation kit #1, which includes our new burlap, two-inch belt, new listing wire, and a dust mask. To help us do that we have Randy Brown, head installer here at Legendary Auto Interiors. Together we’re going to show you why Legendary Auto Interiors is number one with collectors, restorers, and enthusiasts worldwide.

This video can be used as a guideline for any 1968 or 1969 A and B Body model. Let’s get started.

Our first step will be to take the burlap that is included with your bucket front seat installation kit and hog ring it to the top side of our seat springs. This will prevent the foam from working down through the seat springs. To attach the burlap correctly we need to stretch the burlap tight, anchoring it at all four corners first, and then hog-ringing it around the outside perimeter. You want to angle your hog rings downward and towards the center of the seat so it doesn’t prematurely wear through the foam and the seat cover.

Our second step will be to attach our two-inch felt around the entire outside perimeter of the seat springs. This will help pad the seat springs from wearing through the molded foam kit. Once again you’ll need to space those hog rings out about every two to three inches apart and secure it down and inward towards the middle of the seat frame. You’ll notice that the two-inch felt rides on the top side, goes over the outside edge, and extends on the bottom side of the edge of the seat springs.

Now that our burlap and our two-inch felt is attached, we need to find our center point. We need to measure the width of the frame and mark our center point so we can attach our listing wire. This specific model has a listing wire attached down the center. Depending on what model you have, you may require two or possibly three listing wires. They may run front to back, and they may run side-to-side on the front edge.

You’ll see Randy has bent the ends of the listing wire on this specific model of the 69 charger at a 90 degree angle so that the listing wire does not travel front to back. This is a very important step to prepare for your molded foam and your seat cover installation. We want to anchor around the listing wire, through the burlap, and around the seat springs.

As we did on our front seat bottom, we need to repeat the process on our front seat top–putting a layer of burlap over the entire face of the seat springs. We want to anchor the bottom edge, then cut a small area out so there is no buckle in the seat frame hinge area, and then pull some tension towards the top edge and secure the top edge.

Unlike the front seat bottom, the front seat top outer perimeter does not require the two inch felt. Anchor the sides very last, repeat the process on the opposite side, flip the seat over on its face, trim any excess off and secure the burlap to the backside of our front seat top seat frame. Repeat the process on the opposite side also.

Our next step will be to attach our seat back top boards. It’s an oil board panel that just bends and slides into place and is held in by the front seat top seat frame. This is not available with your seat upholstery and will have to be purchased separately, and is also available in our 1966 and 67 models, as well.

We want to repeat the process on our front seat top as we did on our front seat bottom, measuring the distance and striking a centerline so we can attach our listing wire. This is a very important step for installing your seat cover. Some models have two listing wires and sometimes a third that runs horizontally. You want to be careful and measure your originals and see what they look like before you take them apart and install your new ones. You notice that, as we did on our front seat bottom, we want to bend the wire at 90 degree angles so it prevents that listing from traveling top to bottom.

On the models that have multiple listing wires you want to be careful and measure the distance between the seat cover and your original seat frame. This is probably one of the most important steps before installing your seat cover.

Our next step will be to install the headrest plastic base support, and that needs to go on before our molded foam kit. This just screws on with two screws and it will hold the headrest tight if your model car is headrest specific. There are two of these brackets per front seat top. This is an important step if your car has headrests. The bezels, the chrome pieces that you see when the job is all done, actually screw right to this plastic piece.

Now that the first step of our installation is complete–we’ve got our burlap, our two-inch felt, and our listing rods are attached to our seat springs, we’re ready to move on and start to attach our molded foam and then our seat covers.

Depending on what model car you have, your molded foam kit may need to be modified. This specific kit, for the 69 Charger, utilizes installation kit number 11, which comes with four pieces of half inch pre-cut high-density foam that needs to be glued to the face of the molded foam kit. You want to spray a generous amount of general spray trim adhesive, found at your local auto

parts store, on each piece and put the layer of half inch foam directly over the top of the molded foam kit.

You want to let the glue get nice and tacky before you trim it. When you’re trimming it, you need to trim it around the outside perimeter edge. Randy is trimming it with an electric foam knife. If you don’t have one of these, a good pair of scissors, a razor blade, or mom’s old carving knife will do the trick.

We want to repeat the process on our front seat top also. We want to spray a generous amount of general spray trim adhesive on the half inch high density foam and the front side of our molded foam kit. You want to symmetrically place the half inch high density foam in the middle of our foam kit and then trim around the outside perimeter. Again, if you don’t have a foam saw, a pair of scissors, a razor blade, or mom’s old carving knife will do the trick.

Now that our installation kit number 11 is glued to the face of our molded foam kit, we again want to find the center line so we know where to make our cuts down through our molded foam. We want to turn our seat cover inside out, position it on the molded foam where your seat cover is going to go, and mark the listing pocket that’s sewn into the seat cover. This is where we’ll need to make the cut all the way down through the foam. You want to cut a little bit longer all the way down through the foam than the listing pocket so it makes a nice smooth transition on your seat cover installation. After that cut is made you want to peek down through the molded foam and make sure that you can see the listing wire that we attach to our burlap.

Our next step will be to attach our molded foam to the seat frame. We’ll start with the rear by folding the muslin over and hog-ringing it to the seat springs. We want to move on to our

side and our front edge and hog ring through our muslin and through the holes located in the seat frame.

You see Randy’s finishing up on our last side before we move on to our front seat top. Look through where you made your cut in your foam to make sure that you can see the full length of your listing wire. If not, you’ll have to reposition your listing wire.

Now that our front seat bottom is ready for our seat cover we need to move on to our front seat top. Just like we did in our front seat bottom, we need to find our center line then turn our seat cover inside-out to find out where our listing pocket is going to be positioned down through our foam. We need to mark those edges and make a cut down through our front seat top all the way down through. After our cut is made we want to install the molded foam on top of our seat frame. Take a look down through where we’ve made our cut and make sure that you can see the full length of our listing wire. If you can’t you’ll need to reposition the listing wire.

We then want to cut out where we put our headrest bases (the plastic ones) so they are exposed through the foam. Even if your car does not have headrests, it’s a good idea to cut these out. That way, there are no bulges that show from the plastic bumping up against the molded foam. We’ll repeat the process on the opposite side–cutting it with a simple razor blade will work just fine.

Now the headrest support area is trimmed out, we can move down along the side edge of the seat and attach the muslin to our seat frame. This will help secure the molded foam to the seat frame while you’re installing your new seat covers. Then we can move over to the opposite side and repeat the process.

The next step of our seat cover installation is complete. We have our foam secured to our seat springs and we’ll now move forward to our seat cover installation.

The first step of our seat cover installation will be to insert the listing wire into the listing pocket that is sewn into our seat cover. Once that is complete, take a look down through the center cut of your molded foam making sure that you can see the listing wires that we attached to the

top of the burlap. An important step in making sure our seat cover is installed symmetrically is lining it up along the rear edge and then taking the insert pocket that’s sewn into the seat cover

with the listing wire in it, tucking it down through the center cut of the molded foam, and hog-ringing it to the listing rod that is attached on the top side of the burlap to the seat springs. We want to come back and make sure our seat is installed symmetrically, making sure that rear edge is straight.

Our next step will be to roll the back edges of the vinyl over and anchor it with a hog ring through the piping and attach it to the seat spring. This will allow us to keep the cover in place while we wrap the front edges. The seat cover is not constructed to where you can wrap it from the front edge to the back edge, because the cover will tear.

Our next step will be to turn the seat frame over and roll the edges of the front side of the vinyl over the edge of the foam and over the edge of the seat frame. You want to push the edge of the foam up underneath the seat cover so it fills out the vinyl. You’ll notice that the front edges are going to be very tight pulling those edges over. The seat cover is constructed so that if the back half is anchored, the front half will roll over real nice and tight. You’ll want it nice and tight when you roll those edges over. You want to smooth those wrinkles out after you roll those edges over and reach up underneath the seat cover and turn the piping if you have to.

Now that our perimeter edges are all folded over the top of our molded foam, it’s time to anchor the front edge, securing it and starting in the middle and working your way out towards the

sides. That way you’re sure the seat cover is installed symmetrically. It may be a good idea to compress the springs during this application, as it will be easier to make your hog rings go into the seat cover without tearing.

While installing your seat cover you’ll be able to tell how your seat cover is going to look. You can see we’re pulling the wrinkles out as we move along with our hog rings, and chances are if you have your side skirts wrinkle free you’ll be able to flip the seat cover over and that will be wrinkle free on the top side as well.

Our next step will be to attach the rear stretch panel. The rear stretch panel folds along the rear portion of the seat, wraps underneath the bottom of the seat, and is attached to the seat springs. There are two flat panels attached to the outer edges of that rear seat bottom stretch panel that will need to be attached to the seat springs also. There’s one hog ring that attaches and is visible from the outside that will hold that flat panel in place as well.

At any point during your seat cover installation, if you feel you have too many wrinkles in it it’s a good idea to just start over, remove the hog rings, and repeat the process until you have a wrinkle-free seat cover.

Our last step on our front seat bottom seat cover installation will be to cut a hole where the bolt is inserted that attaches our front seat top to our front seat bottom. We cut a hole that’s about a little bit larger than the diameter of the bolt that holds the top to the bottom.

The first step of our seat cover installation will be to insert the listing wire into the listing pocket that is sewn into our seat cover. Once that is complete, take a look down through the center cut of your molded foam making sure that you can see the listing wires that we attach to the top of the burlap. Turn the seat cover inside out and line it up along the bottom edge of our molded foam.

Our next step will be to tuck the listing pocket that’s sewn into the seat cover down through the molded foam and hog ring down through the listing wire that we’ve installed into the seat cover and around that listing wire and around the listing wire that’s installed on the top side of our burlap.

Our next step will be to attach the two listing tabs sewn in the lower side of the front seat top seat cover. This will ensure that your seat cover is installed symmetrically and allow the top edge to be rolled over without the seat cover ripping or tilted to one side or the other.

The next step in our sea cover installation on our front seat top will be to wrap the top edges and the bottom edges over the perimeter. You’ll want to tuck the molded foam up underneath the vinyl as you’re wrapping the vinyl over the edge of the molded foam. This is a good time to work out any minor wrinkles, stretch the vinyl a little bit, take the piping and make sure all the piping is going in the same direction.

Our next step will be to work the side skirt down along the bottom edge. Make sure the cup panel goes over the edge of the molded foam and then the weld is hog-ringed to the bottom edge of the seat frame. You’ll know you have the correct height adjustment when that cup panel just goes around the lower edge of that molded foam kit and the welt lines up along the lower edge of the seat frame.

Our next step of our seat cover installation is the interlocking plastic flap area. You’ll need to interlock the lower portion of the flap first, making sure that the plastic strip is lined up in the center of the seat. After the plastic flaps are interlocked, you want to make sure there are two hog rings, one on the lower side and one on the upper side. This will keep your seat cover from shifting. After the lower portions are attached, you can run hog rings along that entire upper edge where the seat cover meets the seat frame. After the top edge is finished, we can move along to our side edges and attach around the listing and around the rod that runs up and down on our seat frame. You want to repeat the process on the opposite side.

Our next step will be to install the seat back boards. The seat back boards have four clips that interlock and push up against the seat frame and lock it in place and are held in by two screws at the lower base. Sometimes these are buckled and need replacing. If you need to replace these, you can order them through Legendary Auto Interiors. They are the seat back boards. You’ll have to reuse your clips and the lower curved metal piece and you can attach the clips

to the new board. The material that covers that back panel board is included with your seat upholstery kit, but the board is not included with your seat upholstery kit. If you need it you’ll

have to purchase that separately.

Our last step in our seat cover installation will be to attach our front seat top to our front seat bottoms. We have our holes pre-cut where all we have to do is line our hinges up, put our cardboard seat washer underneath the hinge, install the bolt, and tighten down. Then repeat the

process on the opposite side.

Hopefully this video has been helpful for you.